Replaces

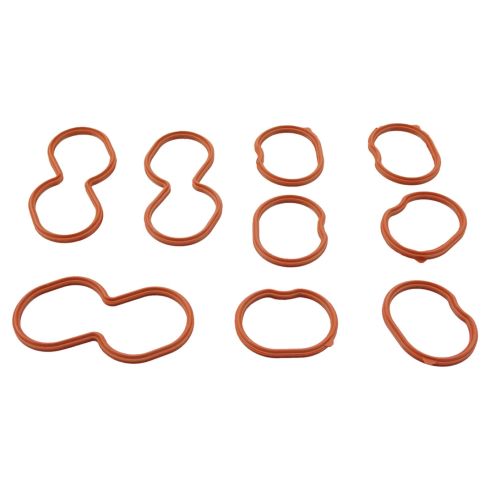

2004 Chrysler Concorde V6 2.7L Intake Manifold Gasket Set TRQ SGA11380

SGA11380

This part doesn’t fit a . Select from parts that fit.

Specify your vehicle's year, make and model to guarantee fit.

Buy in the next and

Orders must be placed by 2pm ET

Part Details

- Silicone

Specifications

- V6 2.7L

Attention California Customers:

![]() WARNING: Cancer and Reproductive Harm - www.P65Warnings.ca.gov.

WARNING: Cancer and Reproductive Harm - www.P65Warnings.ca.gov.

Lifetime Warranty

This item is backed by our limited lifetime warranty. In the event that this item should fail due to manufacturing defects during intended use, we will replace the part free of charge. This warranty covers the cost of the part only.

FREE Shipping is standard on Orders shipped to the lower 48 States (Contiguous United States). Standard shipping charges apply to Hawaii, Alaska and US Territories. Shipping is not available to Canada.

Expedited is available on checkout to the United States, excluding Alaska, Hawaii and US Territories as well as P.O. Boxes and APO/FPO/DPO addresses. Final shipping costs are available at checkout.

Created on:

Tools used

- With the engine running, remove the fuel pump relay from the fuse block. This will stop the engine and release the pressure in the fuel system.

- Use a 10 mm socket and ratchet to remove the upper intake manifold. Disconnect the air pressure sensor. Remove the 8 ten mm bolts.

- Loosen the clamp and the bolt securing the air box. Disconnect the hose and wiring harness. Remove the 13 mm bolt that goes into the throttle body and brace. Pull the gasket off the top of the cowl and now you can remove your intake manifold.

- Pry up the gaskets. Remove the four 10 mm bolts under the intake manifold to get at the fuel rails. Disconnect the throttle position sensor if you need to. Pull the fuel rails up and out. Stuff a clean rag in the intake to keep anything from falling into it. (this would be bad) Disconnect the wiring harness connectors from the injector. Remove the lower intake manifold, having someone help hold the upper intake manifold out of the way. Use a vacuum to remove any debris. Remove the lower intake manifold gaskets. Install the new gaskets.

- Replace your lower intake manifold. Push your fuel rails back into place. Apply some loc-Tite to the four 10 mm bolts and snug them down with a socket and ratchet. Bolt down the intake manifold. Torque the 10 mm bolts to 105 inch/pounds, alternating the bolts you tighten working from the center out.

- Reconnect the air pressure sensor Bolt in the 13 mm bolts securing the bracket to the throttle body, and torque to 15 foot/lbs Reinstall the air box. Tighten the clamp that connects the intake to the throttle body Reconnect the hose and double check all of your sensors are connected. Reinstall the fuel pump relay. Seat the cowl gasket.

Brought to you by 1AAuto.com, your source for quality replacement parts and the best service on the internet. Hi, I'm Don from 1A Auto. I hope this how-to video helps you out. The next time you need a part for your vehicle, think of 1AAuto.com. Thanks.

In this video, we're going to show you how to replace an intake manifold gasket on this 2004 Chrysler Sebring. It has a 2.7 liter V6 and this process is pretty much the same for any vehicle that has a 2.7 liter V6 from this era. You'll need a gasket set from 1aauto.com, flat blade screwdriver, 10 and 13mm socket with a ratchet and extension, torque wrench and you need that torque wrench to measure inch pounds shop vacuum and some Loc-Tite.

Start out using a 10mm socket and ratchet or a wrench and remove the cover that's right next to the throttle intake. Under that, you'll see a 10mm bolt and then all seven of the other 10mm bolts that hold the upper intake manifold down. Disconnect your manifold pressure sensor just by pushing on a tab and pulling and then, I'm going to fast forward here as we remove those eight 10mm bolts. You just basically back them out. The only one that you pull out is the last one that was underneath that cover.

First, you're going to remove your air box, loosen that clamp. There's also usually another bolt down where his forearm is that holds the air box to the frame but you could see, remove the sensor, the hose and then pull the air box up and out. Underneath, there's a 13mm bolt that goes through a brace into the throttle body and we'll remove that. Now, pull of the gasket on top of the cowl just a little bit and you can pull your intake manifold up. You can do this now or you can do it after you take the lower intake manifold out, but just pry up under the gaskets and pop them up and out, and then we'll take the lower manifold out to get the lower ones out. An eight 10mm bolts hold the lower intake manifold in so you see, we just have a 10mm socket and ratchet and we'll remove those.

Obviously right now, you have the inside of your engine exposed so you want to be very careful not to drop anything down in. So be very careful with those bolts. You can see we just went to an air ratchets to save us a little time. As you can see, it's also helpful to have a helper just hold that upper intake up and you can see, as we get towards the back bolts, we have to disconnect the throttle position sensor in order to lift the intake up enough. Now, you want to pull the injectors up and out and you'd see we just grab firmly on to the rail, both parts of it, pull up and out and then grab firmly on the other side, pull it up and out.

Now, you can remove the lower intake manifold and you can see it's helpful to have somebody just grab that upper intake manifold and pull it up out of the way for you. Use a shop vac or any kind of vacuum and just vacuum out any debris that might be in there. As you saw before, the lower gaskets do the same thing, just pry them up and out with a small screwdriver, and then the new ones have a tab on them so they can only go in one way. Just line the tab up correctly, push them down in and we'll just fast forward as we pull the rest of those out and swap the new ones in as well as we put the new upper gaskets on. Again, have somebody help you out by holding up that upper intake and pull up the fuel injector rail and slide your lower intake manifold in, being careful not to displace any of those gaskets.

Now, you can push your fuel injectors right back down into place. I'm going to speed up it up here. We put some Loc-Tite on all these bolts and just kind of thread them in. Here, we're not even tightening down, we're just getting them close. We still want to be able to move the lower intake manifold around. We need to line up one more bolt before we tighten it. Here, for this last bolt where the long bolt from the upper goes in, you want to move it around and line it up. You could see, we put the long bolt in there to kind of hold its place. Now, this is a diagram of the tightening order, so you want to start with that first bolt that's kind of the middle, second bolt and then kind of go out from there. You want to tighten the bolts up in this order.

With that long bolt still in there, we tighten up the first one 105 inch pounds on these bolts and then we'll tighten up the second one. Pull that bolts out of there and then again, like I said, we can tighten up the rest of them to 105 inch pounds. Pull that cowl gasket all away again and lower your intake manifold down into place and push it down on once it's lined up. Just like before, we'll fast forward here as we just pull the bolts down in and start them in and you want to use kind of the same order tighten them up, you start the middle two and work your way out as you torque them and again, we'll torque this to 105 inch pounds.

Reconnect your air pressure sensor and we're going to reinstall that 13mm bolts that holds the bracket to the throttle body and tighten that up to about 15 foot pounds. Put the cover back on top and tighten down that 10mm bolt until it's firm and then we'll reinstall our air box and tighten up the clamp that holds the intake hose, the throttle body, reconnect the hose and reconnect any of the sensors you might have disconnected. Don't forget to reinstall your fuel pump relay or else your car will not start.

We hope this helps you out, brought to you by www.1AAuto.com, your source for quality replacement parts and the best service on the internet. Please feel free to call us toll-free, 888-844-3393. We're the company that serves you on the internet and in person.

Tools used

- Loosen the throttle body hose clamp with a flat blade screwdriver Pull the coolant line out of the intake hose Pull the intake hose off the throttle body Remove the sensor from the intake hose Disconnect the two hoses from the intake manifold Disconnect the MAP sensor from the top of the intake manifold Disconnect the two writing harness from the intake control valves at the front of the intake manifold Disconnect the wiring harness from the throttle body Remove the two 10mm nuts from the throttle body Remove the seven 10mm bolts from the center of the intake manifold Remove the two 10mm bolts from the manifold brackets Remove the two 15mm bolts from the bottom of the throttle body bracket Remove the bracket from the throttle body Remove the two 15mm bolts from the manifold brackets Pull off the intake manifold

- Disconnect the fuel injector wiring harnesses Disconnect the ignition coil wiring harnesses Remove the 10mm bolts from the ignition coils Pull the PCV hose off of the valve cover Disconnect the knock sensor wiring harness Remove the eight 10mm bolts from the passenger side valve cover Remove the two 10mm bolts from the ground wires on the passenger side valve cover Pry up the passenger side valve cover with a flat blade screwdriver Pull the passenger side valve cover up and off Loosen the intake hose clamp with a flat blade screwdriver Pull off the intake hose Remove the breather hose from the driver side valve cover Unclip the wiring harness retainers from the driver side valve cover Remove the seven 10mm studs from the driver side valve cover Remove the 10mm bolt from the driver side valve cover Remove the 10mm bolt from the ground wire on the driver side valve cover Pry off the driver side valve cover with a flat blade screwdriver Pull off the driver side valve cover

- Remove the oil fill cap from the driver side valve cover Remove the old valve cover gaskets Clean any debris or oil from the valve cover gasket channel Lay the new valve cover gaskets into its channel Pry out the ignition coil seals with a flat blade screwdriver Push the ignition coil seals into the valve cover Push the coil seals in using a seal tool or a socket and hammer Twist the oil cap onto the driver side valve cover

- Clean the cylinder head gasket with brake parts cleaner Put the driver side valve cover into place Seat in the fuel injector seals with a pick Start the 10mm bolts into the driver side valve cover Tighten the 10mm bolts to 9 foot-pounds of torque Connect the ground wire to the driver side valve cover Tighten the 10mm bolt for the ground wire Clip the wiring harness retainers to the driver side valve cover Connect the breather tube to the valve cover Push the intake hose into place Put the passenger valve cover into place Start the 10mm bolts into the passenger valve cover Tighten the 10mm bolts to 9 foot-pounds Connect the two ground wires to the passenger valve cover Insert the 10mm bolts for the ground wires Put the ignition coil wiring harness into place Put the ignition coils into place Connect the ignition col wiring harnesses Insert the 10mm bolts for the ignition coils Connect the knock sensor wiring harness Connect the fuel injector wiring harnesses

- Clean the intake manifold surface with brake cleaner Connect the PCV breather hose to the back of the valve cover Remove the old gasket from the upper intake manifold with a pick Press in the new intake manifold gasket Remove the old EGR seal Push on the new EGR seal Put the upper intake manifold into place Click the automatic transmission dipstick into place Start the 10mm bolts for the manifold Tighten the seven 10mm bolts in the center of the manifold to 9 foot-pounds, starting at the center Connect the MAP sensor to the manifold Connect the wiring harnesses for the two intake control valves Put the manifold brackets into place Insert the two 15mm bolts into the brackets Insert the two 10mm bolts into the brackets Connect the PCV hose to the manifold Connect the two hoses to the manifold Connect the throttle body wiring harness Put the throttle body bracket into place Start the two 10mm nuts onto the top of the throttle body bracket Insert the two 15mm bolts into the bottom of the bracket Tighten the two 10mm nuts onto the bracket Push the intake hose onto the throttle body Tighten the intake hose clamp with a flat blade screwdriver Snap the coolant line into the intake hose bracket Connect the MAP sensor to the intake hose Push the intake hose onto intake tube if you disconnected them Tighten the intake tube clamp with a flat blade screwdriver

Hi, I'm Mike from 1A Auto. We've been selling auto parts for over 30 years. We're dedicated to delivering quality auto parts, expert customer service, fast and free shipping, all backed by our 100% satisfaction guarantee. Visit us at 1AAuto.com, your trusted source for quality auto parts.

In this video, we're going to be working with our 2006 Chrysler 300 3.5 liter V6. We're going to show you how to remove and replace both of your vehicle's valve cover gaskets. These can be done individually. However, if you're already in there, it only takes a few more minutes to change the other one and be sure you don't have to take the top of the vehicle's engine off again. If you like this video, please click subscribe. We have a ton more information on this car as well as many other makes and models. If you need parts for your vehicle, you can follow the link down in the description over to 1AAuto.com. Here the items you'll need for this repair.

To remove your intake manifold we'll loosen the clamp at the throttle body with a flat blade screwdriver. You may want to disconnect this sensor. Looks like ours has been glued on because the clip is broken. You can also simply pop it out of the boot. Disconnect these two hoses from the back of the intake located just behind the throttle body. These just pop off by hand. There's one more at the back of the manifold.

Pull back on the red safety tab, push down and disconnect the sensor from the top of the intake, as well as the two electrical connectors at the front. Disconnect the connector from the throttle body. Again, we have one of those little red safety tabs we have to push down. Then we'll push down the tab and remove the connector.

We'll remove the two 10 millimeter nuts from the throttle body, the seven 10 millimeter bolts from the center of the intake manifold here, as well as the two 10 millimeter nuts over on the passenger side of the intake manifold. We'll do this using a 10 millimeter socket and ratchet where we can and a 10 millimeter wrench where it's a little too tight. Remove the two 15 millimeter bolts at the bottom of the throttle body bracket.

We're doing this with a 15 millimeter socket and ratchet. Remove the bracket from the throttle body. There's a 15 millimeter bolt at the bottom of the bracket on the passenger side of the intake manifold, both front and rear. We'll loosen those up with a 15 millimeter wrench until we can slide them off of the studs. Once you've loosened the brackets go ahead and slide them off the studs. Now we'll lift up on the intake manifold, slide it forward to release it from the EGR tube at the back. Once you're off that tube, lift up being careful for that transmission dipstick and remove the manifold from the vehicle.

While the top of the intake manifold is exposed we're going to wad some paper towels in there, just to keep any dirt and debris from getting in there while we're working.

Then you'll want to remove the electrical connectors for each injector which you do by popping up on the red tab until it releases, then pushing down on the black tab, and removing the connector from the injector. You'll repeat this process all the way around.

Disconnect all of your ignition coils by pushing down on the tab, removing the clip. Now we'll remove the 10-millimeter bolts on all of our coils. Remove them from the engine.

Remove the PCV hose from the back of the valve cover. Since we've removed it from our intake, we'll just take it right out, place it off to the side for now. Disconnect the knock sensor connector here. Make sure you put that up somewhere you'll see it so you don't forget to plug it back in.

Then we can lay this whole harness back and out of the way to remove this valve cover. Remove the eight 10 millimeter bolts on the outside edges of the valve cover: four on the top and four on the bottom. We'll do this using a 10-millimeter socket, ratchet, and extension.

There's also a 10 millimeter bolt on the outside center at the bottom of the valve cover gasket that secures two grounds. We'll have to remove that with our 10 millimeter socket and ratchet as well. It's very important that you remember to reconnect all of your grounds as leaving one little ground wire off could wreak havoc on the electrical system and leave you chasing a simple problem.

Using a flat blade screwdriver, pry up around the edges of the valve cover so it's released and remove it from the vehicle.

You may have to remove the intake tube here. We have an aftermarket intake, so we could just tilt it out of the way and remove our hardware. For those of you with the stock air box, you want to use a flat blade screwdriver to loosen this band clamp.

You'll also want to remove this breather hose from the engine, lift up, and remove all of these tabs securing the harness along the valve cover. There seems to be one for very stud except for this one. You may need a small flat blade to help you pry up on this. Move the harness out of the way of your valve cover and we'll need a deep 10-millimeter socket to remove these seven studs, the one 10-millimeter bolt securing the valve cover, as well as the 10 millimeter securing the ground on this side in the same location as the other.

Once all the hardware is loose, you do the same thing. Pry the valve cover up with a small flat blade screwdriver. Once everything is free, go ahead and remove it from the top of your vehicle.

Remove your old gasket from the valve cover. Now there are few schools of thinking here. Some people like to use a gasket sealer to keep it in place with just a couple little drops to hold the gasket into the valve cover. Some people like to use it as extra assurance by filling in this area and then installing their new gasket, coating the bottom of the gasket, and reinstalling the head. Any of these methods are fine. However, for people who don't have gasket sealer, a nice new gasket will do the exact same job for you.

All you have to do is line up the corners. You can see one end is shorter than the other here. Lay the channel in. You can see that we have this groove here. That's what's going to sit into the channel on the valve cover.

Now our gasket wasn't leaking, so we don't have any debris and oil down in here. If you do, clean it out. Make sure all of that is in there, nice and secure, and then we'll move on to removing our coil seals here.

Using a flat blade screwdriver, we'll get up onto the edges of the seal. You just want to wiggle the edge. You can see it lifting out here. These tend to get baked in there pretty good, so it may take a little bit of working to actually get it to come out. Once it's out, take your new seal. See that beveled end? It's going to face here. You just want to get that in. You should be able to push that in and install it fully by hand. Now we'll repeat this process with our remaining two coil holes and then the full process on the other valve cover.

Now this gasket is being a little stubborn, so what we're going to do to make sure it seats in fully and nice and flat is use this bearing and seal installer tool. If you don't have one, using a socket of the correct size or even a flat piece of steel or wood that fits nicely over that top edge and won't contact any of these angled portions will work just fine. We're going to set that on there. Just tap that down until it seats in fully. That's all it needs.

This one is the driver's side, so it includes our oil fill cap. Since that's plastic and we had to use some force to get those seals in, we'll remove that first. Don't forget to reinstall your oil cap after you've finished putting the gasket onto the driver's side valve cover.

Make sure that you wipe off the gasket surface on the cylinder head with a clean paper towel or rag and a little bit of solvent. I'm using a brake cleaner. You can use a variety of different solvents to remove the old dirt and debris. Make sure you don't let any chunks of paper towel or rag fall down into the cylinder head.

Once all that's clean, go ahead and reinstall your valve cover. Be careful that you don't pinch any of the wire harness underneath it. Another thing to be very careful with reinstalling the seals over the spark plug tubes, just put a little bit of down pressure using a pick. Just use that gasket around the tube. We'll do that with the rest of them as well.

Once that's set down into place, go ahead and start tightening down all of your 10 millimeter bolts. Torque your valve cover bolts to a 105 inch-pounds per manufacturer's specification or we're going with 9 foot-pounds because that's approximately what a 105 inch-pounds converts to. Don't forget to reinstall the ground along with its 10 millimeter bolt. You have two of them here both coming from down by the exhaust manifold. Reinstall your harness retainers and your breather tube. Again ours is a little bit different because of our aftermarket intake. We'll also reinstall our intake tube. Now I'm going to leave this loose for now just to make sure that it mounts back up to our intake properly.

Repeat these steps on the opposite side. Reinstall your wiring harness on to the top of the valve cover. Don't forget your 10 millimeter bolt with your two grounds down at the bottom. Make sure nothing is tangled up in there when you reinstall them either.

Reinstall all six of your coil packs. Tighten them down with a 10-millimeter socket and ratchet. Don't forget to reconnect the knock sensor at the back of the motor. Reinstall all of your fuel injector connectors. Don't forget to lock down the red safety tabs as well. Make sure they're all on there, good.

Remove the paper towels from the intake. Clean down this mating surface with some solvent and paper towels or a clean rag. Once again I'm using a brake cleaner here, but there's a variety of solvents you can use to get all that old debris and oil off.

Install your PCV breather tube on the back of the valve cover. You've got a nice little marking on it that says PCV with an arrow so you know which end goes where, and the other end should fall just about over here, where the back of the intake will be.

Remove the old gasket from your intake manifold using a small straight pick here, just to get in there and start popping it out. You should be able to remove the rest by hand. Start your new gasket. Line up. Press that in. Our old EGR seal is damaged so remove that. Install our new one. Make sure it sits all the way back past its edge.

Reinstall your intake manifold, being sure to set the opening for the automatic transmission dipstick into its proper place on the manifold. We'll also want to be careful for the bolts. We'll have to line up our EGR tube as well. Just be mindful of all of these things while we set it into place. Once the EGR tube is set and the intake is laid down onto the lower manifold, clip your automatic transmission dipstick back into place and start all of the 10 millimeter bolts by hand, just a couple of threads, to make sure they're all lined up before we tighten them down.

Tighten up the seven 10 millimeter bolts at the center of the intake. We're not going to tighten these down all the way yet. You just want them a little bit and then we'll have to torque them. Torque these bolts to nine foot-pounds. The manufacturer specification is 150 inch-pounds. However, it's a lot easier to do with this wrench and that number rounds up to about nine foot-pounds. We want to start these in the center and work our way out in a cross pattern.

Reconnect the map sensor. Push the safety into place. Reconnect the two intake tuner valve control. Reinstall the support brackets at the front and rear on the passenger side of the intake. We'll start those 10 millimeters on, just a couple of threads to keep it in place. Using a 15 millimeter socket and ratchet to tighten up those two bolts all the way at the bottom of those support brackets. Once the bottom of the support brackets are tighten down you can use the 10 millimeter socket and ratchet to finish tightening up the top two bolts.

Reconnect the PCV hose and this fitting closest to the EGR tube. We have a small hose here, and a large hose next to that. Reconnect the electrical connector onto the throttle body. Lock the safety tab back into place. You can now set the support bracket back over the throttle body bolts. Make sure it doesn't get caught up in any of the wiring down below. We'll spin our two 10 millimeter nuts on at the top by hand, just to keep that in place. Reinstall the two 15 millimeter bolts at the bottom of the bracket by hand. Tighten up the two 15 millimeter bolts at the bottom of the bracket with your socket and ratchet. Tighten up the two 10 millimeter nuts at the top.

Install the other end of the intake boot onto the throttle body. Tighten it up with your flat blade screwdriver. Reinstall the coolant tank line bracket on the side of the intake tube. Reinstall the map sensor into the intake tube. Earlier when we removed our intake, we wanted to wait until we had the intake tube reinstalled to make sure this all lined up properly. Now that we've got it where it needs to be we'll go ahead and tighten that down.

Thanks for watching. Visit us at 1AAuto.com for quality auto parts, fast and free shipping, and the best customer service in the industry.

SGA11380

877-844-3393

Monday - Friday 8:00am - 9:30pm ET

Saturday - Sunday 8:00am - 4:30pm ET

Specify your vehicle's year, make and model to guarantee fit.

This part doesn’t fit a . Select from parts that fit.